Our Story

Historical roots

The Department of Energy Engineering has a rich history in combustion research and heat engine development for practical applications. Over the past hundred years, several departments were established and merged at the Faculty of Mechanical Engineering of the Budapest University of Technology and Economics. The contribution of, e.g., Donát Bánki, György Jendrassik, and János Miklós Beér are world famous. Due to the conflicts after the Second World War, several talented students and researchers had to leave the country, hence, our university.

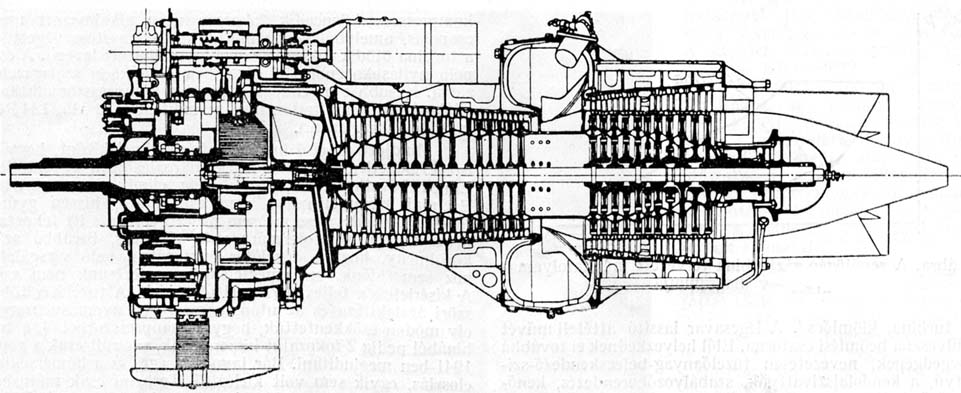

Our laboratory, named after György Jendrassik, always focused on developing heat engines and novel concepts, including gas turbines, steam turbines, furnaces, boilers, and internal combustion engines. The fundamental combustion research was focused on combustion chamber noise and pollutant emission measurements. Besides research, our department always had a strong relationship with the industry, which helped us focus on real systems.

Early years

The Department of Energy Engineering participated in a EU5 research program (ENK5-CT-2000-00311, 2002-2005) in which a Capstone C-30 micro gas turbine was modified to run on wood gas with as low LHV as 6.3 MJ/m3. Besides the gas-fueled micro gas turbine, a liquid-fueled one was also acquired that was originally designed for diesel oil and kerosene. The research was continued with modifying the liquid fuel system to utilize aqueous alcohol, which is the by-product of the alcohol industry, and they are obliged to dispose of this waste. Upon the success of this project, investigation of significantly less volatile fuel, crude vegetable oil, was started, which provided the PhD research of Attila Kun-Balog under the supervision of Dr. Krisztián Sztankó. To save the micro gas turbine from flooding with oil, one of its burners was removed and subjected to exhaustive tests. During this period, Viktor Józsa joined this research as a BSc student. The project continued with developing a new combustion test rig, which was burdened by the lack of funding. However, the group mastered the combustion of crude rapeseed oil without high emissions or notable contaminations on the equipment. Then Viktor finished his MSc and started a PhD under the same supervisor, Dr. Krisztián Sztankó.

From the lab to international recognition

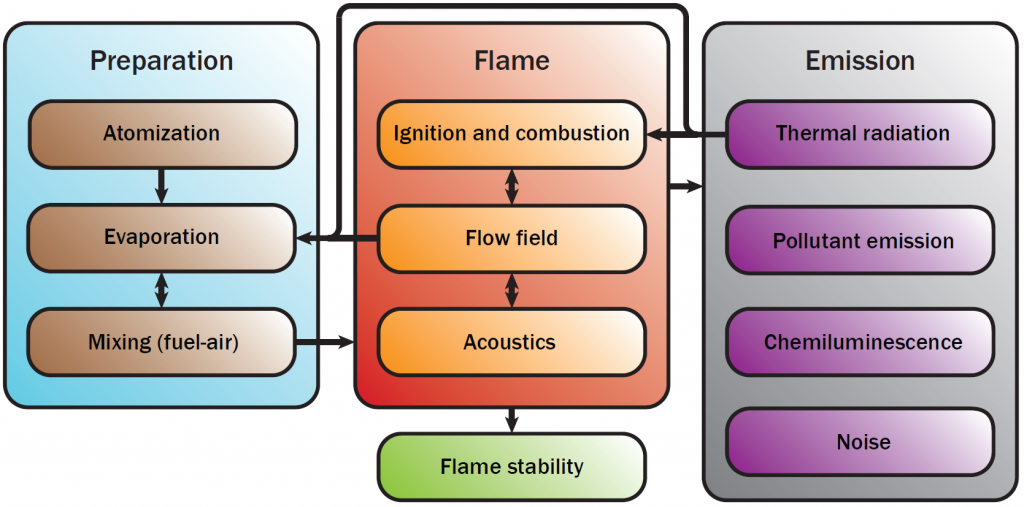

The complexity of liquid fuel combustion is briefly presented in the left image. It was shortly realized that the research requires huge support to understand each process, therefore, several student projects were announced from the fall semester of 2013 to the spring semester of 2015. As a result, Viktor has supervised six and seven papers submitted to the Scientific Conference of Students in 2015 and 2016. Among the students, four of them started a PhD since 2017. They are András Urbán, Dávid Csemány, Gyöngyvér Hidegh, and Dániel Füzesi. Their topics in order: atomization, evaporation, chemiluminescence measurement and test facility design & construction, and CFD. The contribution of the team members greatly contributed to achieving international recognition.

Establishment of the Combustion Research Group

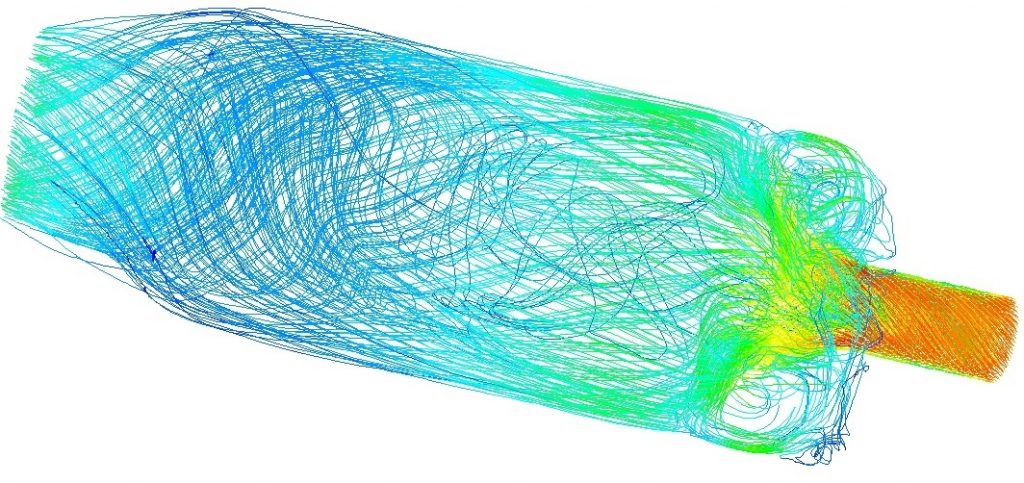

The formation of the Combustion Research Group was never stated explicitly. However, its birth can be considered the start of the OTKA-FK 124704 grant, funded by the National Research, Development and Innovation Fund of Hungary, which was 01 September 2017. Viktor Józsa took the lead, Attila Kun-Balog and Dr. Krisztián Sztankó joined as senior researchers. In 2019Q4, the test rig passed the successful hot tests after spending two years with designing and building the system. The primary goal was to end up with a robust, versatile, and highly modular dual fuel design that enables setting several operating parameters without restrictions. The initial aim was to design a regular swirl burner to investigate the combustion of various renewable fuels, but the airblast atomizer led to a completely different flame shape, shown on the right. At elevated pressure and low equivalence ratio, distributed combustion appeared that is a unique feature since it was observed by fellow researchers by using either flue gas recirculation (either inner or outer) or combustion air dilution by inert gas (typically N2 or CO2). The NOX emission of distributed combustion was 50% lower than that of V-shaped flames, and the single-digit emission easily fulfills all the current emission standards. Our goal is to understand the operation of distributed combustion better and publish the design guidelines of such burners.

What does the future hold?

Climate change forces humanity to leave the coal in the mines and the crude oil in the fields. However, there are no known viable alternatives available at the moment that can replace combustion, especially in the transportation and air travel. The number of wind turbines and solar cells is rapidly growing, and their costs are falling. Nevertheless, our power consumption is still rapidly increasing, making the situation more complicated. Therefore, it is always a top priority to understand the fundamentals and end up with versatile solutions that can also be used in completely different fields.

If you have questions or feel motivated to do some research together, do not hesitate to contact us.