Atomization

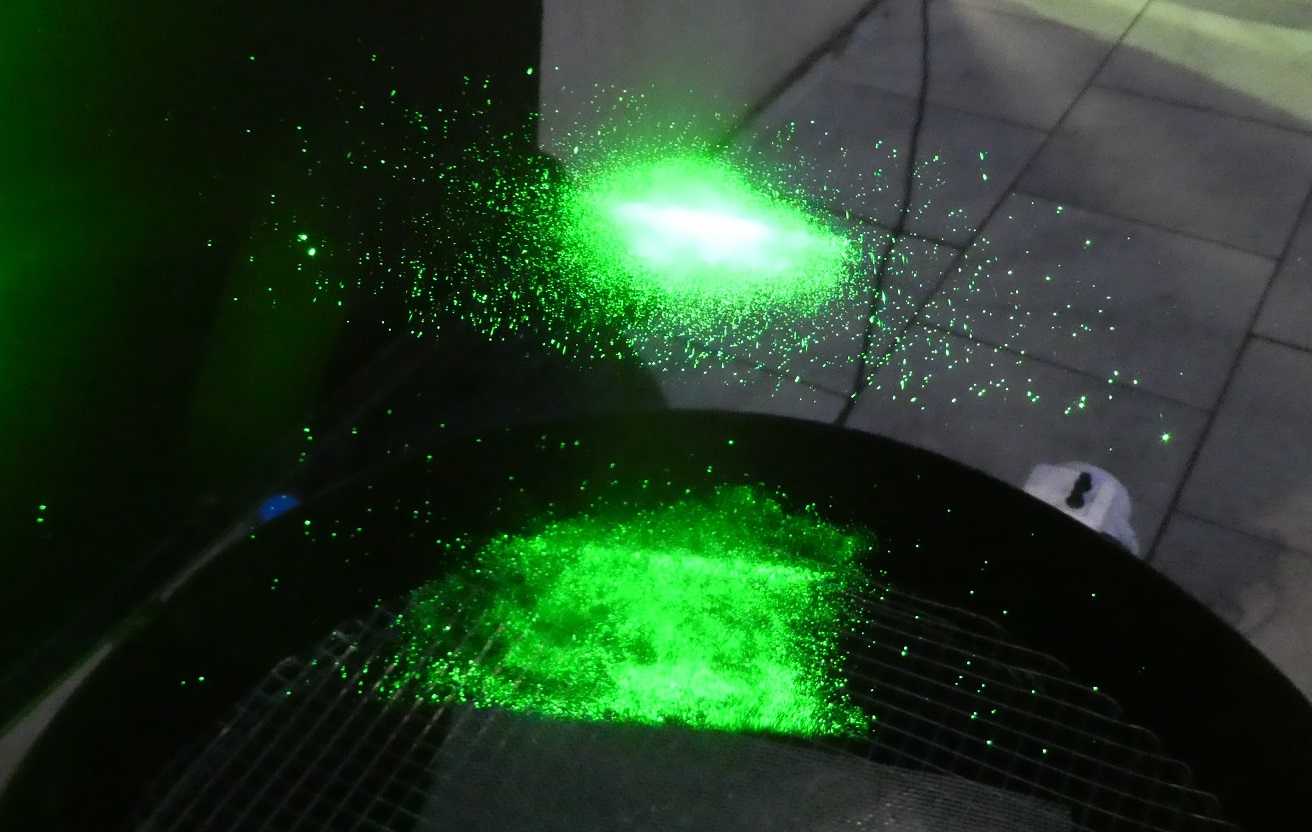

Spray characterization

It used to be a single parameter, the surface-to-volume diameter or Sauter Mean Diameter, which was of primary interest of sprays in combustion applications. Nowadays, the tightening pollutant emission standards and the demand for highly fuel-efficient applications made detailed spray analysis a hot topic that involves statistics and modeling.

Airblast atomization, which is extensively investigated by our research group, is an excellent platform to analyze the atomization process since the characteristic dimensions of the nozzle have a marginal influence on the final spray. Besides combustion, the range of applications is wide, which makes it an excellent topic for base research that has and will have several uses in the industry.

Statistical analysis

Spray characteristics can be modeled by probability density functions. The variation of the parameters shows the evolution of the spray. However, the trends depend on the spray regions and the atomizer type. Big data tools are necessary to draw general conclusions to find general trends.

A classical problem in multiphase flow and flow seeding is properly determining the gas phase velocity. Our research group solved this problem by evaluating numerous data sets on airblast atomization, and the theory was validated by measurements on other atomizer types. The method will be published soon.

The necessary number of droplets for spray characterization depends on the application and the desired parameters to be derived. A goal of our research group is to develop a robust and straightforward framework for spray data processing.

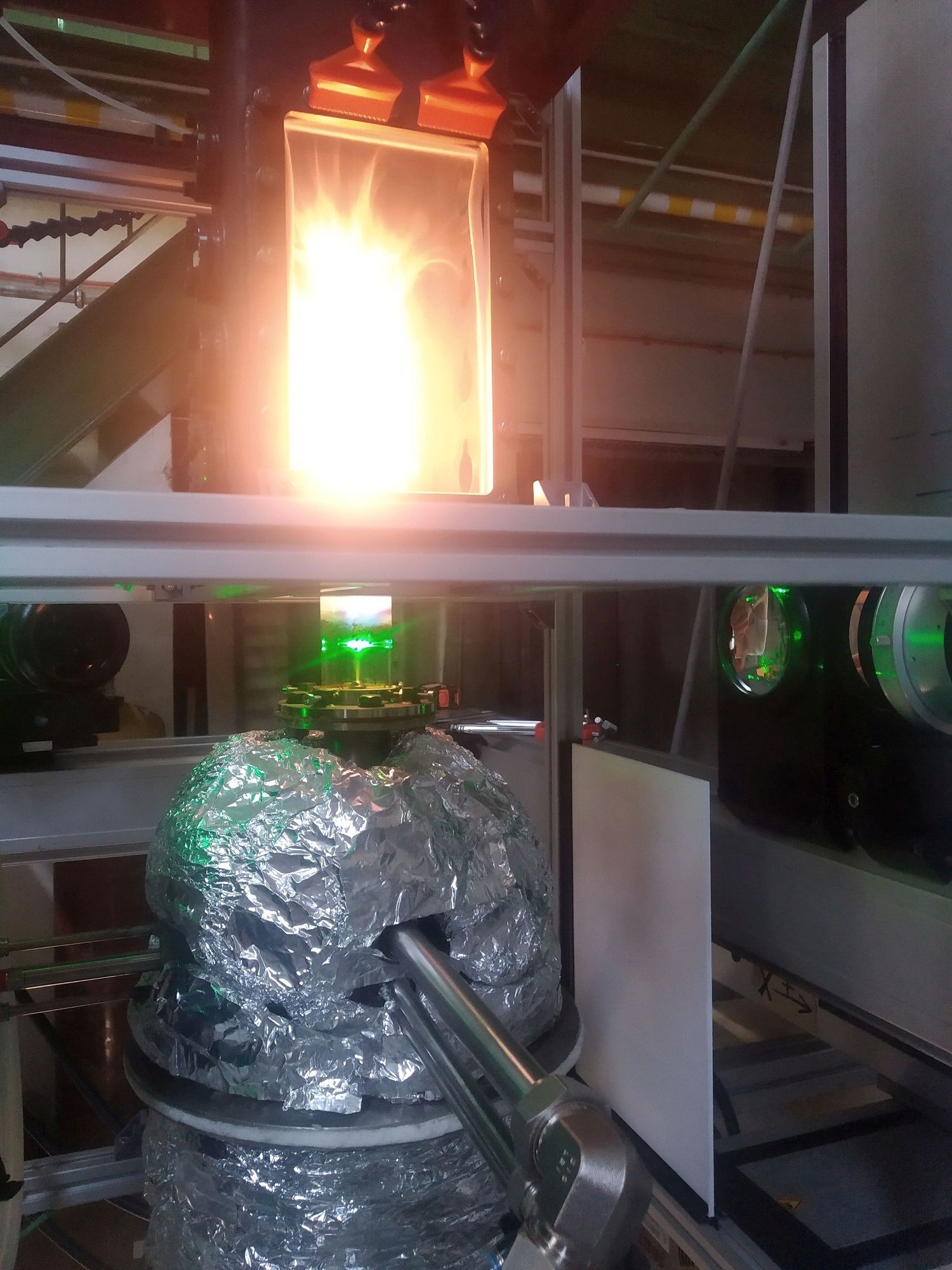

Reacting flows

Spray measurement in reacting flows is rarely discussed in the literature since atomization alone contains several unresolved mechanisms in a typically one-way connection with the flame. Since spray evaporation is a must for complete combustion and hence excellent fuel economy, proper spray characterization is essential.

Evaporation modeling has two challenges. The first is solving the intrinsic interactions in the spray, including droplet collisions and liquid jet breakup. The second is the thermal modeling of the droplets and their vaporization.